-

PhoneNeed help?

PhoneNeed help?

Call + 45 98 51 11 44  Video

Video-

PDF

PDF

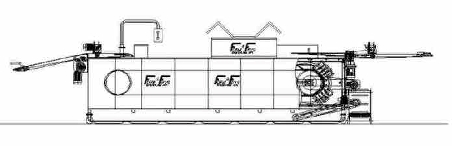

About the pizza edge folding machine

About the pizza edge folding machine

The Pizza folding machine is the result of many years of experience in automatic folding of typical folded dough products, such as the typically "Danish Pastry" and puff pastry products.

Form & Frys Maskinteknik has developed a pizza folding machine to serve the high volume pizza manufacturers with machines built to handle production capacities as high as 24 meter/min. or 200 pizzas per minute.

Using well-proven technology from other types of machines, Form & Frys has been building pizza folding machines since the mid 90's. The machines can be constructed with or without filling under the folded dough edge. The patented folding process, folding only the edge and leaving the center untouched resulting in a superior quality pizza with true rising edges.

CRUST OR STUFFED PIZZAS

Product size: 16", 12", 10", 9", 8", / 400 mm, 300 mm, 250 mm, 225 mm, 200 mm, 180 mm.

Rubber folding wings fold the edge of the pizza dough in approximately 5 synchronized steps, with certain number of folding wings (e.g.20) determined by the size of the pizza.

High capacity, labor-cost savings, machine strength and superb product uniformity are some of the major advantages of this machine. This is obtained by making a large volume of products on a relative slow and smooth production flow.

The operation is carried out in one continuous flow, by means of our logic groove and roller system.

The Pizza folding machine

- Unmatched capacity (up to 50 rows/min on a F&F standard machine)

- Customer can order almost any size and shape.

- 2-4 pizza pr. row (depending on size).

- Built as a wheel-in, wheel-out unit.

- Maximum output of, dough preparing equipment.

- Synchronizable with the F&F Rotary Fillers.

- Easy to clean and maintain. (very maintenance friendly)

Capacities: Pizza machines production rate max: |

|

|

16" 2 row machine: |

3.600 pizzas per hour |

|

12" 3 row machine: |

7.200 pizzas per hour |

|

10" 3 row machine: |

8.100 pizzas per hour |

|

8" 4 row machine: |

12.200 pizzas per hour |

|

Production speed: |

24 meter per minute |

Hygiene

The machine includes a CIP (cleaning in place) system. Which consists of two systems.

One setup is primarily for dry cleaning during production, using air, via a nozzle that travels across the surface of the folding cassettes, continually blowing air, preventing any built-up in the folding head during production (used especially for productions around the clock).

The second set up is for wet cleaning. Water is used to assist in cleaning all vital parts of the folder cassettes via spray nozzles installed under and inside the machine.

MATERIALS

The machine is produced predominantly in stainless steel, evoprene and POM (polyoxymethylene / also called Delrin). All parts in direct contact with the product are produced in FDA / USDA/ food approved materials.

|

Working height: |

approx. 1.250 mm. |

|

Total Length: |

approx. 6.200 mm. |

|

Total width: |

approx. 2.500 mm. |

|

Rework height: |

approx. 1.800 mm. |

|

Dough width: |

approx. 1.150 mm. |

|

Weight total: |

approx. 4.500 Kg. |

|

The above dimensions include the inlet, discharge and rework conveyors. |

|

The heights of the inlet conveyor, discharge conveyor and scrap conveyor are made to fit the existing line.

The pizza industry continues to be a growing business. Pizza producers are constantly looking to introduce new high-quality products to the market.

Form & Frys has, through their know-how and innovative ideas, proven to be a valuable partner in developing new products.

The Pizza Rotary Filling machine

The rotary-filling machine has a large rotating drum with pistons, retracting when in the hopper and ejecting when right above the dough product. The relatively low peripheral speed ensures a capacity as high as 90 Strokes per min.

The unique concept of the rotary-filling machine gives primarily two major advantages.

- An outstanding high capacity, even with shaped deposits.

- A very gentle treatment of the mass as there is no compression whatsoever, even particles can be deposited, without any damage.

Having trouble deciding what sizes your production should run?

Contact us for further information about our Free Standing Fold Machine

Free standing Folding machine Download PDF here

.png&width=452&compression=100)

.png&width=452&compression=100)

.png&width=452&compression=100)

.png&width=452&compression=100)

- Back to product information