-

PhoneNeed help?

PhoneNeed help?

Call + 45 98 51 11 44  Pictures

Pictures Video

Video-

PDF

PDF

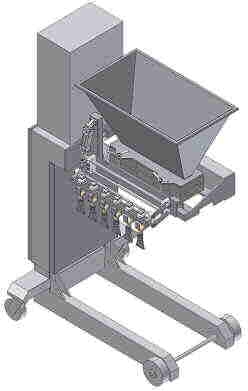

A multi purpose and precision multi row filling and depositing machine, Form & Frys Maskinteknik offers the GW 600 Gear Wheel Depositor.

From 40 grams mini muffins to big cupcake deposits of 1000 grams and even continuous deposits, or interrupt strips for savoury products, the GW 600 machine is flexible, easy to operate and due to the cantilevered C frame very mobile.

Due to the cantilevered construction the GW can be placed over virtually any conveyor system and is height adjustable to fit.

In addition to the Gear Wheel pump the unit is fitted with a pneumatically controlled diving nozzle boom, which can be used for injecting fillings, placing icing or filling moulds.

The standard unit is for a 600mm wide line with 6 nozzles. For larger deposits nozzles can be grouped together or blocked by replacing the gear wheels in the pump house with an infill piece.

Custom-built configurations up to 800mm are possible.

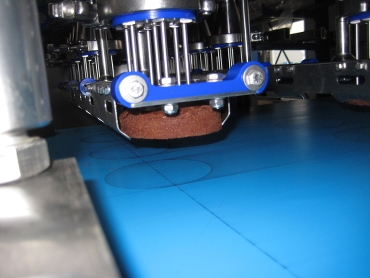

Deposits with particles / Sensitive products

Particles such as chocolate chips in muffin batters are deposited with minimum of damage. The recommended particle size is 5x5x5mm. The GW600 treats aerated products gently, maintaining the product structure.

Electronic control, touch screen.

The machine can be controlled via a line signal (guillotine), or photocells.

The GW is controlled via a panel view touch screen.Operation is chosen as 12 individually program selections are available, direct from menu.The individual settings can be fine tuned during production and memorized for next use of same program number.

Materials

The machine is produced predominantly in stainless steel and POM (polyoxymethylene). All parts in direct contact with the product are, of course, produced in food-approved materials.

Cleaning

The GW 600 is designed to be easy to clean. Many of the parts are small enough to be put into an industrial dishwasher. With minimum extra effort it is possible to fully dismantle the gear wheel assembly making the unit suitable for meat and fish fillings.

Technical specifications: |

|

Capacity: |

35 deposits/min. (depending on deposit size) Hopper volume 35 liters |

Deposit volume: |

50 - 1000g 7.000 g/min constant deposit |

Air pressure: |

80PSI / 5.5bar - 3-5cfm / 84-142 |

Power: |

3phase 16amp. |

- Back to product information

- Back to product information