-

PhoneNeed help?

PhoneNeed help?

Call + 45 98 51 11 44  Video

Video-

PDF

PDF

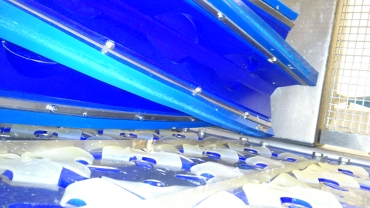

The ODIN Folding Machine is a combination between the steady Hercules and the adaptable Charlie, both of which are machines that are proven in industrial environments. The Hercules servicing high capacity industrial bakers and the Charlie servicing semi automated bakers needing flexibility and quick retooling.

Form & Frys Maskinteknik has developed the ODIN Folding Machine to service the higher capacity bakers who still require a degree of flexibility. The ODIN Folding machine can reach speeds exceeding 16.000 products per hour.

Form & Frys Maskinteknik have been building dough folding machines since 1987 prior to 1992 it was the Alfa Folding machine. This was replaced by a new generation of machines built using the technology still in use today. This technology has been adapted to many and varied product applications.

To optimize performance, Form & Frys Masinteknik have developed filling machines that perfectly fit the Odin Machine but can also be used for “standalone “ production.

Download the ODIN brochure here

Materials

The machine is produced predominantly in stainless steel, POM (polyoxymethylene trade name Delrin in other parts of the world) and evoprene. All parts in direct contact with the product are produced in FDA / USDA-approved materials.

The Rotary Filling Machine

To optimize the function and possibilities of Form & Frys industrial folding machines, we have developed a filling machine, which fits the needs exactly.

The basic function principle of the rotary fi ller is a rotating drum with pistons, retracting when in the hopper and ejecting when right above the dough product. It can be seen as a rotating version of the well known slide-plate depositor used within the industry.

Due to the large capacity of this machine type and the possibility for placing a shaped deposit, fi llings containing sensitive particles or special shaped fi llings can now also be deposited at speeds never before seen.

The unique concept of the rotaryfilling machine gives primarily two major advantages:

• An outstanding high capacity, even with shaped deposits, up to 45 strokes.

• Changable drum for different shapes.

.png&width=452&compression=100)

.png&width=452&compression=100)

.png&width=452&compression=100)

- Back to product information

- Back to product information